Universal Robot

UR10e

Cobot (collaborative robot)

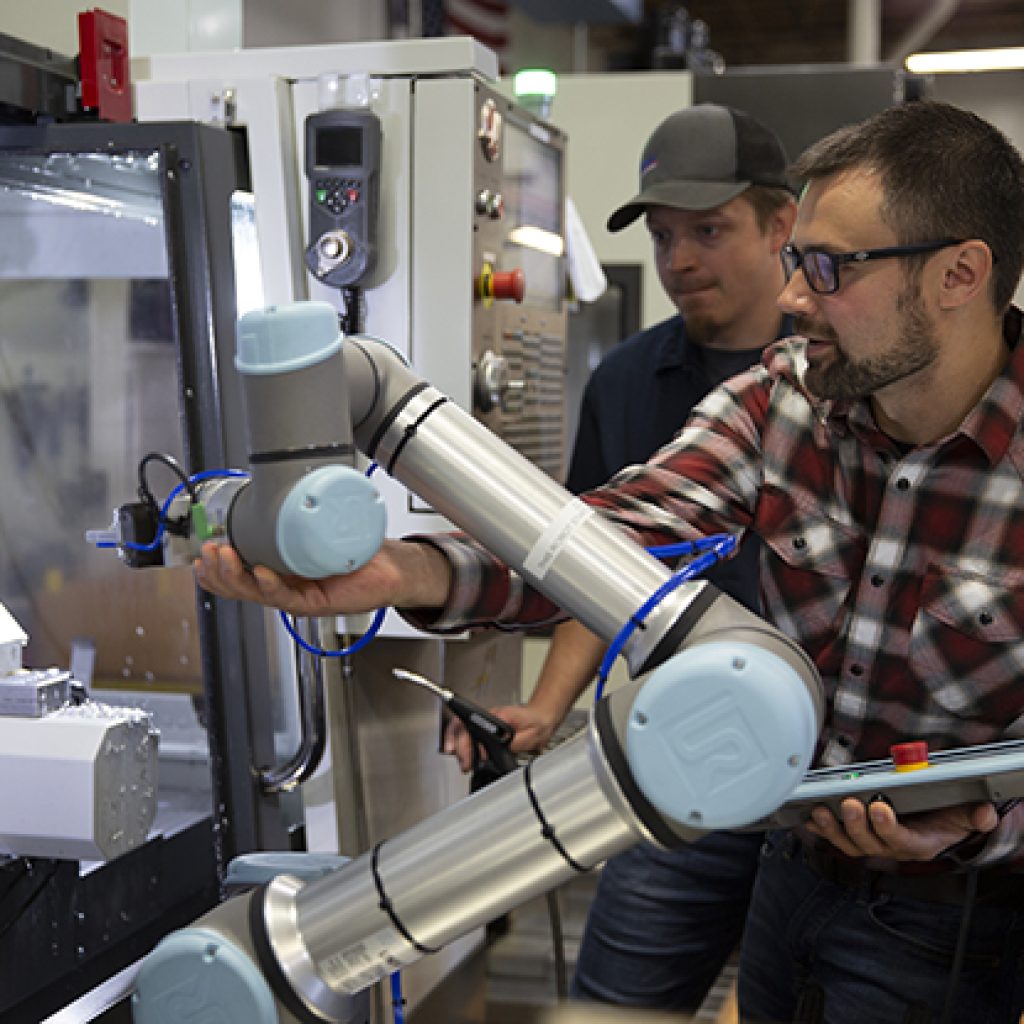

The UR10e is a medium-duty industrial collaborative robot (cobot) built by Universal Robots. It’s known for being versatile, with a long reach and high payload capacity. This makes it ideal for a wide range of applications in different industries.The UR10e is a powerful and versatile cobot from Universal Robots. It stands out for its ability to handle heavier loads and reach farther than many other cobots, making it suitable for a wider range of tasks.

FEATURES

Fast deployment

The out-of-box experience for an untrained operator to unpack the cobot, mount it, and program the first simple task is typically less than an hour.

Space saving

Our cobot’s small footprint opens opportunities to automate tasks in existing manufacturing setups where floorspace is often set and at a premium.

Power consumption

Automating tasks gives you the possibility to run tasks autonomously without constant monitoring of your employees. In addition, UR cobots use less electricity than traditional industrial robots.

Collaborative and safe

All UR cobots come with built-in safety features, including force-sensing technology and collision detection. These features allow our cobots to work alongside you without the need for safety barriers or cages, increasing productivity and promoting a safe working environment.

INDUSTRIES

Manufacturing

Manufacturing is a major adopter of the UR10e. Its ability to handle heavier loads makes it suitable for machine tending, where it can handle material loading and unloading tasks, assembly tasks, improving consistency and production speed. On packaging and palletizing lines, the UR10e's reach comes into play, allowing it to efficiently handle goods over a larger workspace.

Logistics and Warehousing

The UR10e streamlines operations in logistics and warehousing facilities. Its precision and strength assist with palletizing tasks, ensuring goods are stacked securely and efficiently. It can also be integrated into sorting systems, handling and segregating items based on pre-programmed criteria. Additionally, the UR10e can be deployed in order fulfillment, picking and placing items to speed up order processing.

Food Processing

This industry demands a delicate touch alongside efficiency. The UR10e can handle packaging and material handling tasks within food processing facilities, ensuring hygiene and precision. Beyond that, some food prep tasks can be automated using the UR10e, such as sorting or picking delicate items like fruits or vegetables.

Agriculture

Repetitive tasks like planting seeds or harvesting fruits can be automated using the UR10e. Its ability to handle delicate objects carefully makes it suitable for working with crops. Furthermore, it can be deployed in sorting and grading agricultural products based on size or quality.

Research and Development

The UR10e's adaptability makes it a valuable tool in research labs. Its precise movements and user-friendly programming allow researchers to automate various tasks involving material handling or manipulation in experiments. This frees up scientists' time for more complex analytical work.

Other Potential Applications

It can be used in construction for tasks like brick laying or welding. In the retail sector, it can be deployed for stock picking and retrieval tasks. The UR10e's potential applications continue to grow as businesses explore new ways to leverage collaborative automation.

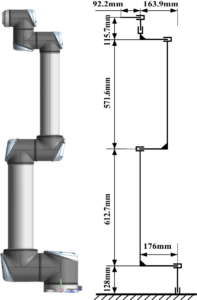

TECH SPECS

detailed specifications

Weight | 28.9 kg / 63.7 lb |

|---|---|

Payload | 10 kg / 22 lbs |

Reach | 1300 mm / 51.2 in |

Joint ranges | +/- 360° |

Speed | Base and Shoulder: 120°/s. Elbow, Wrist 1, Wrist 2, Wrist 3: 180°/s. Tool: Typical 1 m/s. / 39.4 in/s |

Repeatability | +/- 0.1 mm / +/- 0.0039 in (4 mils) |

Footprint | Ø190 mm / 7.5 in |

Degrees of freedom | 6 rotating joints |

Control box size (WxHxD) | 475 mm x 423 mm x 268 mm / 18.7 x 16.7 x 10.6 in |

I/O power supply | 24 V 2A in control box and 12 V/24 V 600 mA in tool |

Communication | TCP/IP 100 Mbit: IEEE 802.3u, 100BASE-TX Ethernet socket & Modbus TCP |

Programming | Polyscope graphical user interface on 12 inch touchscreen with mounting |

Noise | Comparatively noiseless |

IP classification | IP54 |

Power consumption | Approx. 350 watts using a typical program |

Collaboration operation | 15 Advanced Safety Functions Tested in accordance with: EN ISO 13849:2008 PL d EN ISO 10218-1:2011, Clause 5.4.3 |

Materials | Aluminum, ABS plastic, PP plastic |

Temperature | The robot can work in a temperature range of 0-50°C |

Power supply | 100-240 VAC, 50-60 Hz |

Cabling | Cable between robot and control box (6 m / 236 in) Cable between touchscreen and control box (4.5 m / 177 in) |

NAVIGATION SENSORS

EXTERNAL DIMENSIONS | 1061 x 854 x 1224 mm |

|---|---|

WEIGHT | 80 kg (176 lbs) |

MAXIMUM SPEED | 80 kg (176 lbs) |

GROUND CLEARANCE | 80 kg (176 lbs) |

OPERATING AMBIENT TEMPERATURE | 80 kg (176 lbs) |

INGRESS PROTECTION | 80 kg (176 lbs) |

OPERATING TIME | 80 kg (176 lbs) |

NAVIGATION SENSORS

EXTERNAL DIMENSIONS | 1061 x 854 x 1224 mm |

|---|---|

WEIGHT | 80 kg (176 lbs) |

MAXIMUM SPEED | 80 kg (176 lbs) |

GROUND CLEARANCE | 80 kg (176 lbs) |

OPERATING AMBIENT TEMPERATURE | 80 kg (176 lbs) |

INGRESS PROTECTION | 80 kg (176 lbs) |

OPERATING TIME | 80 kg (176 lbs) |

GALLERY

Videos

Contact Us

The latest Robot news and resources contact straight legal Point.

1168 Hamilton St #400, Vancouver, BC V6B 2S2

Telephone: +1-825-888-9393

bob@newagerobots.com, info@newagerobots.com

Useful Links

Copyright © techite all rights reserved.