ABB Industrial Robotic Arm

IRB 1200

Industrial robotic arm

The ABB IRB 1200 is a versatile 6-axis industrial robot designed to streamline material handling and machine tending processes in manufacturing.The ABB IRB 1200’s combination of speed, flexibility, durability options, and advanced control system makes it a compelling choice for a wide range of industrial automation applications. Its compact design and diverse mounting options allow for easy integration into existing or custom-designed workspaces, while its strong performance and available upgrades make it suitable for even demanding environments.

FEATURES

Food Grade Lubrication option

This option features food grade lubrication on all axes, wrist flanges, motor covers, and IP67 protection against dust and liquid. NSF H1 food-grade lubrication throughout is designed to meet the constraints of food and beverage applications.

Foundry Plus 2 option

The Foundry Plus 2 option enables the robot to withstand harsh environments and meets the requirements for use in metal die casting, sand casting, forging, and machining applications. The Foundry Plus 2 is IP67 compliant from base to wrist, meaning that the robot’s electrical compartments are sealed against liquid and solid contaminants

Cleanroom option

This option means that the cleanroom robot is sealed, which reduces particle contamination and prevents grease and oil leakage into production areas for products and devices such as electronics, pharma, and lab automation. The cleanroom robot is ISO 14644-1 Class 3 certified, making it ideal for manufacturing settings requiring exceptional cleanliness and minimal particle emission, all while maintaining top-notch speed and performance

Compact

The IRB 1200 has no offset in axis two, which results in a longer stroke than other small robots and it, meaning it can be placed very close to the work piece and still be functional. This allows for a much more compact installation when the robot is mounted on the ceiling inside a small cell, such as in electronics machining or polishing applications. The robots’ large usable working area contained in a small package leads to shorter cycles and more compact machines

INDUSTRIES

Automotive

The IRB 1200 can handle tasks like: Part transfer: Moving components between workstations on an assembly line. Machine tending: Loading and unloading materials from CNC machines or presses. Quality control: Performing inspections or testing on manufactured parts.

Electronics

In electronics manufacturing, the IRB 1200 is suited for: Component placement: Precisely positioning delicate electronic components on circuit boards. Soldering: Automating soldering processes for consistency and efficiency. Assembly: Helping assemble various electronic devices.

Food and Beverage

With special food-grade lubrication, the IRB 1200 can be used for: Packaging: Picking and placing food items into packaging containers. Palletizing: Arranging packaged goods onto pallets for storage or transport. Filling: Filling containers with precise amounts of liquids or food products.

Pharmaceutical and Medical Devices

The cleanroom option makes the IRB 1200 suitable for: Aseptic packaging: Handling and packaging sterile medical devices. Lab automation: Automating tasks in laboratories, such as sample handling or compound dispensing. Assembly: Helping assemble medical devices in a sterile environment.

Other Industries

The IRB 1200's can find applications in general manufacturing, plastics processing, and even metal fabrication for tasks involving: Sorting: Separating different parts or materials based on size, shape, or other characteristics. De-molding: Removing parts from molds after casting or forming processes. Dispensing: Applying adhesives, sealants, or other materials with precise control.

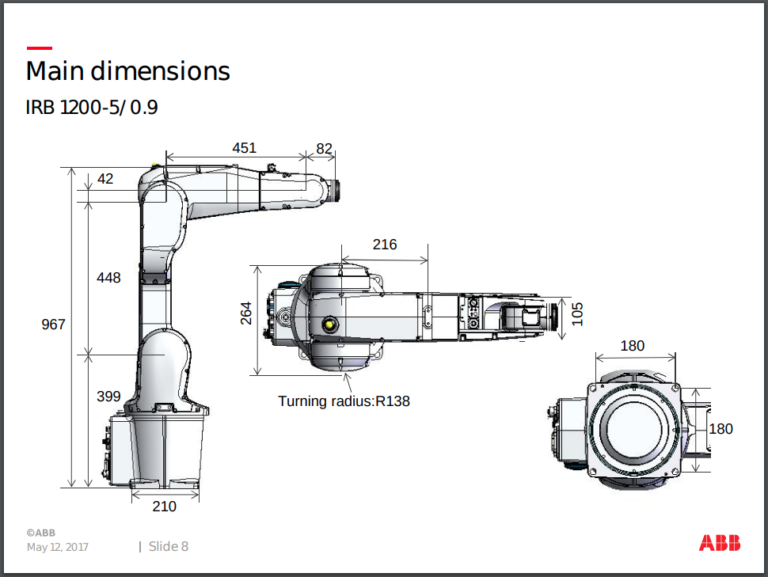

TECH SPECS

PLATFORM

Robot version | IRB 1200-5/0 |

|---|---|

REACH (m) | 0.9 |

PAYLOAD | 9.5 |

ARMLOAD | 0.3 |

NUMBER OF AXES | 6 |

PROTECTION | Standard IP40 Option IP67 and Foundry Plus 2 |

CLEANROOM | Option ISO class3 |

OTHER SPECS

Food Grade Lubricant | Option, only available with IRC5 |

|---|---|

MOUNTING | Any angle |

CONTROLLER | OmniCore E10, C30, C90XT, IRC5 Compact/IRC5 Single Cabinet |

INTEGRATED SIGNAL AND POWER SUPPLY | 10 signals on wrist |

INTEGRATED AIR SUPPLY | 4 air on wrist (5 Bar) |

INTEGRATED ETHERNET | One 100/10 Base-TX ethernet port |

SUPPLY VOLTAGE | 1061 x 854 x 1224 mm |

|---|---|

RATED POWER TRANSFORM RATING | 80 kg (176 lbs) |

POWER CONSUMPTION | 80 kg (176 lbs) |

ROBOT BASE | 80 kg (176 lbs) |

ROBOT HEIGHT | 80 kg (176 lbs) |

ROBOT WEIGHT | 80 kg (176 lbs) |

SOFTWARE

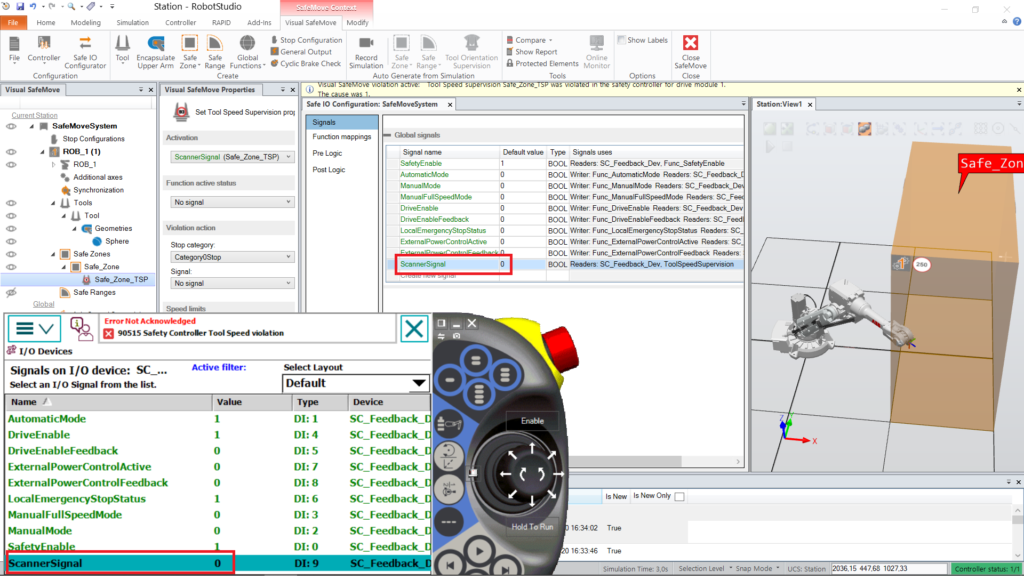

SafeMove2: This software is an integrated safety feature within the IRC5 controller. SafeMove2 plays a critical role in ensuring safe interaction between the IRB 1200 and human workers. It monitors the robot’s movements and surroundings, restricting its motion when necessary to prevent collisions and safeguard personnel. This allows for collaborative workspaces where robots and humans can operate in close proximity without compromising safety.

GALLERY

Videos

Contact Us

The latest Robot news and resources contact straight legal Point.

1168 Hamilton St #400, Vancouver, BC V6B 2S2

Telephone: +1-825-888-9393

bob@newagerobots.com, info@newagerobots.com

Useful Links

Copyright © techite all rights reserved.