Epson SCARA Robot Arm

Epson SCARA Robot Arm

Industrial Robot (SCARA - Selective Compliance Articulated Robot Arm)

The Epson SCARA Robot Arm is a high-performance industrial robot designed to automate a wide range of manufacturing processes. With its precision, speed, and versatility, this robot arm excels in tasks such as pick and place, assembly, packaging, and more. Its compact design allows for seamless integration into existing production lines, optimizing space utilization. Equipped with user-friendly programming interfaces, the Epson SCARA Robot Arm streamlines setup and operation, enabling manufacturers to enhance productivity and efficiency while reducing operational costs.

FEATURES

High Speed and Precision

The Epson SCARA robot arm offers rapid and precise movements, enabling efficient handling and assembly tasks in manufacturing environments, thus maximizing productivity.

Compact Design

With its compact footprint, the Epson SCARA robot arm can be easily integrated into confined spaces on production lines, optimizing floor space utilization and flexibility in deployment.

High Payload Capacity

Despite its compact size, the Epson SCARA robot arm boasts a high payload capacity, allowing it to handle heavier objects with ease, thus expanding its applicability across diverse industrial applications.

Low Maintenance Requirements

Engineered for reliability and durability, the Epson SCARA robot arm requires minimal maintenance, resulting in reduced downtime and lower total cost of ownership for manufacturers.

User-Friendly Programming

Featuring intuitive programming interfaces, the Epson SCARA robot arm allows for quick and easy setup, reducing programming time and enabling operators to adapt to new tasks swiftly.

Versatile End-Effector Compatibility

Designed to accommodate various end-effectors and tooling options, the Epson SCARA robot arm offers versatility in performing a wide range of tasks, from pick and place operations to intricate assembly processes.

INDUSTRIES

Automotive Manufacturing

The Epson SCARA Robot Arm plays a crucial role in streamlining production processes by performing tasks such as part assembly, welding, painting, and quality inspection. The high-speed and precision capabilities of the Epson SCARA Robot Arm contribute to increased productivity, improved product quality, and enhanced worker safety in automotive plants.

Electronics Manufacturing

In the electronics manufacturing industry, the Epson SCARA Robot Arm is employed for pick-and-place operations, soldering, packaging, and testing of electronic components and devices. Its speed, accuracy, and repeatability make it ideal for handling delicate electronic parts with precision, resulting in increased production efficiency and consistent product quality.

Food and Beverage Packaging

Epson SCARA Robot Arms find application in the food and beverage packaging industry for tasks like sorting, filling, sealing, and labeling products. They help streamline packaging processes, minimize product wastage, and maintain cleanliness in production environments.

Pharmaceutical Manufacturing

In pharmaceutical manufacturing facilities, Epson SCARA Robot Arms play a crucial role in tasks such as dispensing, sorting, and packaging medications and medical devices. Their precise handling capabilities and adherence to strict cleanliness standards make them suitable for use in cleanroom environments. By automating repetitive tasks, these robots increase productivity, reduce errors, and ensure the consistent quality of pharmaceutical products.

TECH SPECS

SPECIFICATION

Feature | Specification |

|---|---|

Model Number | T6-602S |

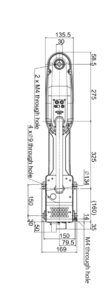

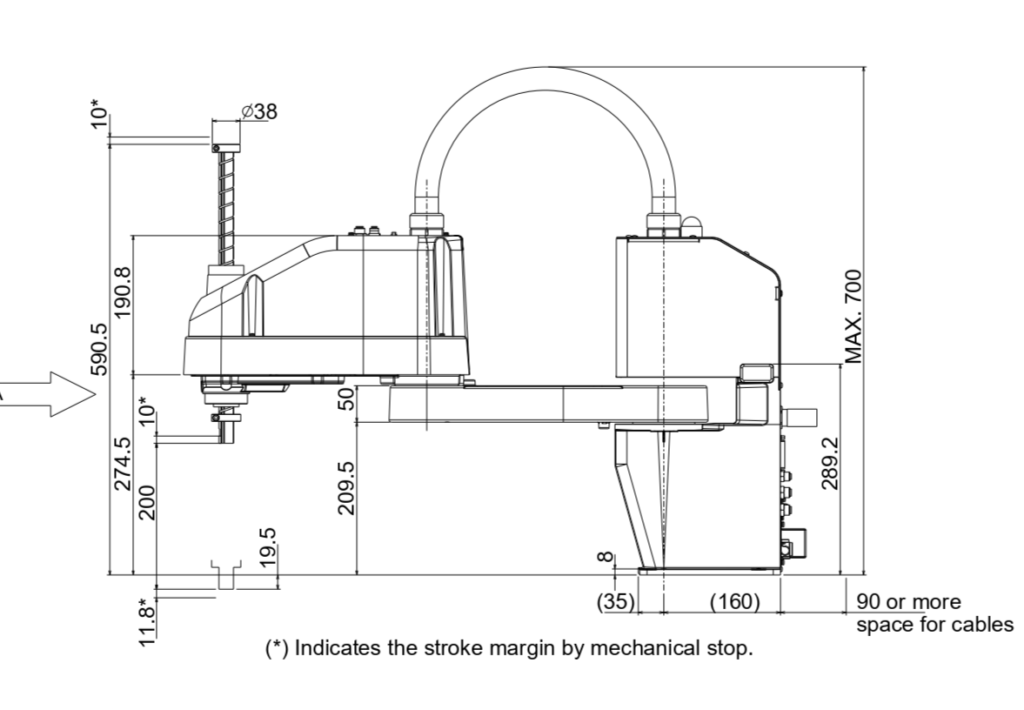

Arm Length (Joints #1+#2) | 600 mm |

Weight (cables not included) | 22 kg |

Max. Operation Speed | |

* Joint #1-2 | 4180 mm/s |

* Joint #3 | 1000 mm/s |

* Joint #4 | 1800 deg/s |

Repeatability | |

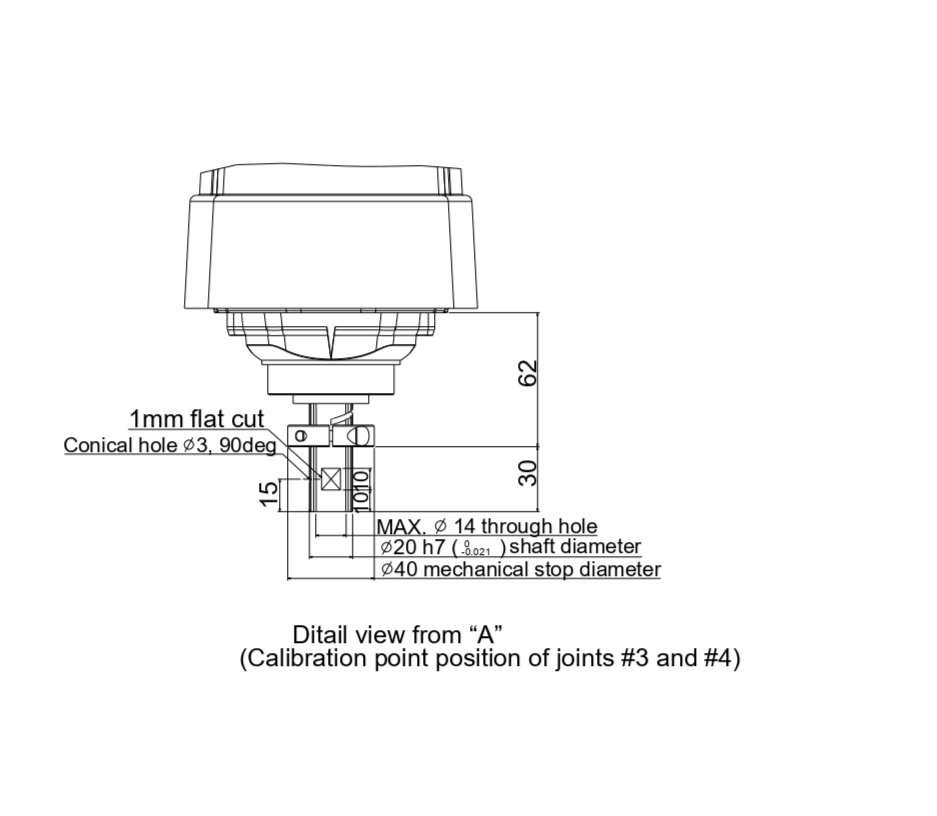

* Joint #1-2 | ± 0.04 mm |

* Joint #3 | ± 0.02 mm |

* Joint #4 | ± 0.02 deg |

Payload (Load) | |

* Rated | 2 kg |

* Max | 6 kg |

Standard Cycle Time*2 | 0.49 sec |

Join#4 Allowable Moment of Inertia*3 | |

* Rated | 0.01 kg-m² |

* Max | 0.08 kg-m² |

Joint #3 Down Force | 83 N |

Installed Wire for Customer Use | Hand I/O: IN6/OUT4 (D-sub 15pin) <br> User I/O: IN18/OUT12 |

Installed Pneumatic Tube for Customer Use | ø 6 mm x 2, ø4mm x 1: 0.59 MPa (6 kgf/cm²: 86 psi) |

Power / Cable Length | AC100-240V/5m |

Applicable Controller | Built-in controller |

Installation Environment | Standard |

Safety Standard | CE mark |

SOFTWARE

Husky Observer is pre-installed with Clearpath’s OutdoorNav Autonomy Software, enabling planning and execution of missions with an easy-to-use web interface for autonomous navigation and outdoor environments.

Learn more about OutdoorNav Autonomy Software

GALLERY

Videos

Contact Us

The latest Robot news and resources contact straight legal Point.

11, William Grant Road, Markham, Ontario, L6E 1R8

Telephone: +1-825-888-9393

bob@newagerobots.com, info@newagerobots.com

Useful Links

Copyright © techite all rights reserved.